Stoichiometry of Maltose

Fermentation to Ethanol

©

James

M. Gossett (March 25, 2012) Questions/Comments?

![]()

![]() Overview

Overview

![]() Stoichiometry of Ethanol Production From Maltose

Stoichiometry of Ethanol Production From Maltose

![]() Contribution of Ethanol to Apparent Brix

Contribution of Ethanol to Apparent Brix

![]() Measurement of %ABV Using Brix Refractometry

Measurement of %ABV Using Brix Refractometry

![]() Derivation of Calculator Equations

Derivation of Calculator Equations

![]() Evaluation of The Method: Comparing Estimated and Measured %ABV

Evaluation of The Method: Comparing Estimated and Measured %ABV

Consideration

of two factors is required to estimate ethanol (EtOH)

production from initial and final refractometer

(Brix) measurements:

(i)

the stoichiometry of maltose fermentation to EtOH; and

(ii)

the contribution that the resulting EtOH makes to Brix.

In this

section, the stoichiometry is considered.

Wort is a complex

mixture of carbohydrates, but I will simplify by assuming that the major

fermentable fraction is maltose, C12H22O11 (FW

= 342 g/mol). Carbohydrate composition certainly

varies among beer-types, but maltose is by far the sugar at highest

concentration in most worts, constituting about 50%

of wort carbohydrate.10

Given that wort carbohydrate is only

about 65% to 75% fermentable (and maltose is 100% fermentable), then maltose

certainly constitutes far more than 50% of the fermentable carbohydrate

fraction of wort. The next highest sugar fractions are

glucose and maltotriose, which are generally each

present at only about 1/5th the levels of maltose. [See Table 2.3 in Boulton

and Quain.10] Since maltose (a

disaccharide) has a chain-length midway between glucose (a monosaccharide) and maltotriose (a trisaccharide),

that also makes it a particularly good stand-in for the fermentable extract of wort.

Balling’s Equation

Carl J. N. Balling1,2 observed

the following stoichiometry:

2.0665 g

fermentable extract ---> 1 g EtOH + 0.9565 g CO2

+ 0.11 g losses Eq [1]

Assume

“fermentable extract” = maltose, and that “losses” are settled biomass from

yeast synthesis (which I will represent as total suspended solids, TSS).

Balling’s

studies date from 1843 -1865, but his stoichiometry has stood up reasonably

well. It is established3,4 that Balling’s stoichiometry

somewhat under-predicts ethanol production; or, put another way, using it in

reverse to predict original extract (OE, original gravity in degrees Plato) for

a given %ABW tends to over-predict OE.

Several modern researchers3,4 have

raised theoretical objections to Balling’s stoichiometry — e.g., that

evaporations of water and alcohol are ignored; that net losses from yeast growth differ

significantly between lagers and ales;

that Balling's CO2 values are assumed (1 mol

CO2 per mol EtOH)

and not measured; and that not all CO2 produced will be evolved

(some will remain dissolved in the wort]).

Nonetheless, tinkering with Balling’s equation has ultimately resulted in

remarkably marginal improvements.

For example,

after lengthy, comprehensive analysis of large datasets, followed by derivation

of new equations, Cutaia et al. concluded,3

“Nonetheless, it is tribute to the analytical skills of Balling that he could

determine the Balling constants … in the mid-1800s. The original Balling values

are embedded in the brewing literature and their use … is reported to slightly

overestimate the original extract. Application of Balling’s original equation

to the datasets in this paper similarly overestimates original wort extract in all datasets but one. However, OE, RE and OHww measurement errors may overshadow

differences in the Balling constants. For these reasons and since the Balling

equation is embedded in the brewing literature (and culture!) we do not expect

(nor recommend) adaptation of a new Balling equation.”

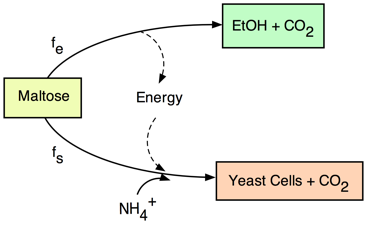

Bioenergetics &

Stoichiometry: Another Approach

Yeast use maltose as both carbon source for synthesis of new

yeast cells, and as electron donor for energy production. Energy is required for synthesis of new cells

from maltose, and yeast derive that energy from

fermentation of maltose to EtOH under anoxic

conditions. Thus, we can consider

that a fraction, fe,

of maltose is used for energy; and a fraction, fs, is

used for synthesis. Note that fs + fe

= 1.

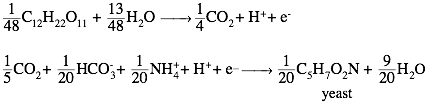

Energy reaction

![]() Eq [2]

Eq [2]

Synthesis

reaction

To

write a synthesis reaction, converting maltose to yeast cells, we must have a

model for the composition of yeast.

Here we are presented with some difficulty: composition varies significantly with

species, strain, growth conditions, and stage of fermentation (i.e., early vs.

late).10,12

Simmonds,12 in averaging a number of

different sources, reported the organic portion (dry weight basis) of yeast is

about 90% of total dry weight, and in terms of major elements, the organic

portion is 48.3% C, 6% H, 34.5% O, and 10.6% N. This translates to a molar formula for

the major elements in the organic fraction of yeast of C4.03H6O2.16N0.76 (MW = 99.56 g/mol). Given the oxidation states of H (+I), O

(–II), and N(–III)[i.e., protein], such a

formula suggests that the average oxidation state of carbon is +0.149. It also means that in carbonaceous

oxidation of yeast to CO2 (producing +IV carbon), the number of electrons evolved would be:

4.03*(+4 - 0.149) = 15.52 for

C4.03H6O2.16N0.76. Thus, 1 electron equivalent (eeq) of yeast would be (1/15.52)*99.56 = 6.41 g VSS or

about 6.41/0.9 = 7.12 g TSS.

[Note: VSS = volatile suspended

solids, a standard measure of organic particular matter; TSS = total suspended

solids, a standard measure of total particulate matter (organic + ash).]

Rosen11(cited in Boulton and

Quain10) reported an elemental model for yeast VSS of C4.02H6.5O2.11N0.43P0.03. Let’s ignore the phosphorus

content, as being much smaller than the content of the other elements, giving C4.02H6.5O2.11N0.43

(MW = 94.52 g/mol). This implies the average oxidation state

of carbon is –0.246. [Note the more reduced state of carbon than if the empirical

formula of Simmonds is used, owing to the significantly lower nitrogen content

in Rosen’s formula.] In carbonaceous oxidation

to CO2 (+IV carbon), the number of electrons evolved would be: 4.02*(+4 + 0.246) = 17.07 for C4.02H6.5O2.11N0.43.

Thus, 1 eeq of yeast would be (1/17.07)*94.52 = 5.54

g VSS or about 5.54/0.9 = 6.16 g TSS.

An often-used9 empirical formula for the

elemental content of microbial biomass is C5H7O2N

(113 g/mol).

This wasn’t intended so much for yeast as for bacteria. In this formula, the average oxidation

state of carbon is zero – i.e., between those of the models of Simmonds

(+0.149) and Rosen (–0.246). The number of electrons evolved in carbonaceous

oxidation of C5H7O2N would be 20. Thus, 1 eeq

of C5H7O2N would be (1/20)*113 = 5.65 g VSS or

about 5.65/0.9 = 6.28 g TSS. This

is slightly higher than Rosen’s formula would predict (6.16 g TSS), but lower than

Simmonds’ (7.12 g TSS).

Conclusion: Given that yeast composition can

vary significantly depending upon strain and growing conditions, there is

little to recommend against the use of C5H7O2N as an empirical formula

for the ratio of major elements in the organic fraction of yeast. Though it was

formulated to model the principal elements in the organic fraction of bacterial

biomass, I am using it here to approximate the organic solids of yeast cells. It is an assumption positioned between

the sources10,11,12 consulted on yeast composition.

Thus,

the two half-reactions that are combined to produce a reaction for synthesis of

yeast cells from maltose are as follows:

If we keep only the relevant terms and

normalize to one mole of maltose, the synthesis reaction becomes

![]() Eq [3]

Eq [3]

Yeast

cells (dry weight basis) are about 90% organic matter, 10% inorganic

matter. Since the formula weight of

C5H7O2N is 113 g/mol,

the 2.4 moles of C5H7O2N appearing on the

right-hand side of the synthesis reaction corresponds to 2.4(113)/0.9 = 301.3 g

total suspended solids (TSS).

Complete

Stoichiometry (combined energy and synthesis reactions)

The complete stoichiometry for maltose

fermentation is thus given by:

fe*Eq[2] +

(1 – fe)*Eq[3] Eq [4]

Our

quest, then, becomes estimation of fe, the net

fraction of maltose used for energy in fermentation of wort.

McCarty5-9

developed a method that uses

bioenergetics (based on thermodynamic data and observations about microbial

efficiencies of energy capture and utilization) to estimate cellular yields

from substrate degradation. With

estimates of specific decay/maintenance rate, the method allows fe to be estimated. For those readers who are familiar

with the method (e.g., students in my CEE6570 Biological Processes graduate class at

Cornell University), details are provided in the following. Readers unfamiliar with

the method will undoubtedly be lost; a tutorial is presented here.

∆G0(W), kcal

Rd: ![]() –10.0

–10.0

Ra: ![]() +7.592

+7.592

∆Gr

= 2.408 kcal

∆Gp = –1.455 kcal

![]()

![]()

![]()

Both

ae

and Y are gross yields (albeit

in different units), uncorrected for maintenance/decay, which should be

appreciable in prolonged fermentation.

Without such corrections, ae is the same as fs, the fraction of

malt used in biosynthesis; this means, uncorrected for

maintenance/decay, bioenergetics predicts fe = 1 – fs =

0.82 (clearly too low).

A

rational approach to correct for maintenance/decay: Consider that most of the yeast growth

occurs in the first few days, followed by autolysis ("endogenous

decay") over an extended, batch fermentation period. As reasonable

values, let's choose a specific decay rate, b

= 0.02 d-1

and a fermentation period of 30 days. The basis for selecting the decay

rate is that 2% per day is typical for anaerobic processes at sub-ambient

temperatures. The basis for selecting a period of 30

days? That's a typical fermentation period. Obviously, both decay

rate and fermentation period would be temperature-dependent, but in opposite

directions (i.e., decay rate would increase with temperature, while fermenation period would decrease with temperature).

Thus, their product is relatively insensitive to temperature, and it's the

product bt that

appears in the relevant equation.

Considered as an extended batch process (t= 30 d, b = 0.02 d-1)

fs = ae exp(–bt) = 0.179 exp[–0.02(30)]

= 0.10

------>

fe

= 0.90

Its use with Eq

[4] gives the following stoichiometric relationship:

1 g maltose ---> 0.484 g EtOH + 0.494 g CO2 + 0.088 g TSS Eq [5]

Comparison With

Balling’s Equation

Expressed per g maltose fermented,

Balling’s equation, Eq [1], becomes

1 g maltose

---> 0.4839 g EtOH + 0.4629 g CO2 +

0.0532 g TSS Eq [6]

What value of fe

used in Eq [4] corresponds to Balling’s

observations? The following Table was

created for different assumed values of fe:

|

Per gram maltose

consumed |

|||

|

fe |

g EtOH |

g CO2 |

g TSS |

|

0.90 |

0.484 |

0.494 |

0.088 |

|

0.91 |

0.490 |

0.496 |

0.079 |

|

0.92 |

0.495 |

0.498 |

0.070 |

|

0.93 |

0.500 |

0.500 |

0.062 |

|

0.94 |

0.506 |

0.502 |

0.053 |

|

0.95 |

0.511 |

0.504 |

0.044 |

|

0.96 |

0.516 |

0.506 |

0.035 |

|

0.97 |

0.522 |

0.508 |

0.026 |

|

0.98 |

0.527 |

0.511 |

0.018 |

|

0.99 |

0.533 |

0.513 |

0.009 |

|

1.00 |

0.538 |

0.515 |

0.000 |

|

|

makes EtOH agree

with Balling |

||

|

|

makes TSS agree with Balling |

||

It can be seen that no single value of fe

will give agreement with Balling for all three products (EtOH,

CO2, and TSS). In fact,

no reasonable value of fe allows

agreement for CO2. Since

Balling’s CO2 value was clearly based on the assumption of equal moles EtOH and CO2

produced in fermentation (rather than being based on actual measurement), there

is no reason we should concern ourselves with fitting it. Because Balling ignored the net CO2

that will be produced in synthesis of cells from maltose (Eq[3]), Balling’s equation

is necessarily going to underestimate CO2 produced per gram

maltose. On the other hand, not all

CO2 produced will be evolved (lost) from the beer; some will remain

dissolved. Balling’s theoretical

underestimation of CO2 production might unintentionally correct

(somewhat) for this. Nonetheless,

Balling’s underestimation of wort losses (CO2

and settled yeast cells) could, in part, explain his stoichiometry’s tendency

to underestimate ethanol production (%ABW): if wort losses

are underestimated, then final gravity is overestimated, lowering estimated EtOH weight percentage because the denominator (total final

wort mass per 100 g initial wort

mass) has been overestimated.

Conclusion

So, what

value of fe

am I going to use? In the end, I

elected to use a value consistent with both the bioenergetics analysis and with Balling’s

EtOH observations, since predicting EtOH production is my main objective:

---------> fe = 0.90

This

is the value employed in my Brix-based, %ABV calculator. Its use gives the

following stoichiometric relationship:

1 g maltose ---> 0.484 g EtOH

+ 0.494 g CO2 + 0.088 g TSS Eq [5]

Eq [5]

differs from Balling’s, Eq [6], in the following manner: My stoichiometry predicts greater CO2

evolution than Balling’s, since he ignored CO2 evolved from cell

synthesis; and

my stoichiometry predicts greater cell synthesis. Since only 10% of maltose is used in

synthesis, these differences in stoichiometry are not very important. Furthermore, they only come into play in

estimating final wort mass through subtraction of

evolved CO2 and settled biomass solids from initial wort mass. Since most of the wort

mass is water, these stoichiometric differences in estimated losses of CO2

and biomass solids are not very important. It is, however, more theoretically

satisfying to make these changes:

there is no theoretical justification for ignoring CO2

evolved in synthesis. It is also satisfying that application of

bioenergetics can predict a value of fe in reasonable agreement with Balling's

observations. In all this, it should be noted that I am walking in

the footsteps of other researchers who have raised theoretical objections to

Balling, but who have, in the end, not improved significantly upon his work.3,4

References

& Resources

1. Balling,

Carl. J. N., Die Bierbrauerei. Verlag von Friedrich Temski: Prague, CHZ, 1865.

2. Balling,

Carl J. N. “Die Gärungschemie” I-IV, Prague 1845, “Die Gärungschemie” I-III. 2.

Aufl., Prague 1854, “Lehrbuch der Bierbrauerei” I-II, 3. Aufl. Prague 1865.

3. Cutaia, A. J., A-J Reid, and R. A. Speers. “Examination

of the relationships between original, real and apparent extracts, and alcohol

in pilot plant and commercially produced beers,” Journal of the Institute of Brewing, 115(4), 318-327 (2009).

4. Neilson,

H., A. G. Kristiansen, K. M. Krieger Larsen, and C. Erikstrom. “Balling’s formula - scrutiny of a

brewing dogma,” Brauwelt Int., 25, 90-93 (2007)

5. McCarty,

P. L., “Energetics and Bacterial Growth,” in

S. D. Faust and J. V. Hunter (ed.), Organic

Compounds in Aquatic Environments, Marcel Dekker, Inc., New

York, pp. 495-512 (1971).

6. McCarty,

P. L., “Stoichiometry of Biological Reactions,” Progr. Water Technol.,

7,

157-172 (1975).

7. McCarty,

P. L., “Energetics of Organic Matter Degradation,” chapter 5 in Mitchell, R.

(ed.) Water Pollution Microbiology,

91-118, John Wiley & Sons (1972).

8. McCarty,

P. L., “Thermodynamics of Biological Synthesis and Growth,” The Proceedings of the 2nd International

Water Poll. Research. Conf., Tokyo,

1964. Pages 169-199, Pergamon Press (1965).

9. Rittmann, B. E., and P. L. McCarty, Environmental

Biotechnology: Principles and Applications, McGraw-Hill, New York, NY

(2001).

10. Boulton. C. and D. Quain, Brewing Yeast

& Fermentation. Oxford, U.

K., Blackwell Science Ltd. (2001).

11. Rosen, K. “Preparation of yeast for industrial use in the

production of beverages.” In Biotechnological

Applications in Beverage Production (eds C. Cantarelli and G. Lanzarini), pp.

164-223. Elsevier

Science Publishers, New York (1989).

12. Simmonds,

C., Alcohol,

Its Production, Properties, Chemistry, And Industrial Applications. Macmillan & Co. (1919).

![]()

![]() Overview Contribution of EtOH to Brix; Measurement of %ABV

Overview Contribution of EtOH to Brix; Measurement of %ABV ![]()